New resins for old papers

In the furniture and flooring industry melamine decorative surfaces are used. In the first production step decorative papers are impregnated with melamine resins and industrially pre-dried in an impregnating channel. Tailored resins and their penetration behaviour thereby fix the final product properties. It is essential to know these properties – so on the basis of an objective method of determination we are able to predict this behaviour. This allows the use of new resins and the processing of difficult and sometimes old decorative papers. Thus an economic competitive advantage for the industrial partner is given.

With objectivity to new properties

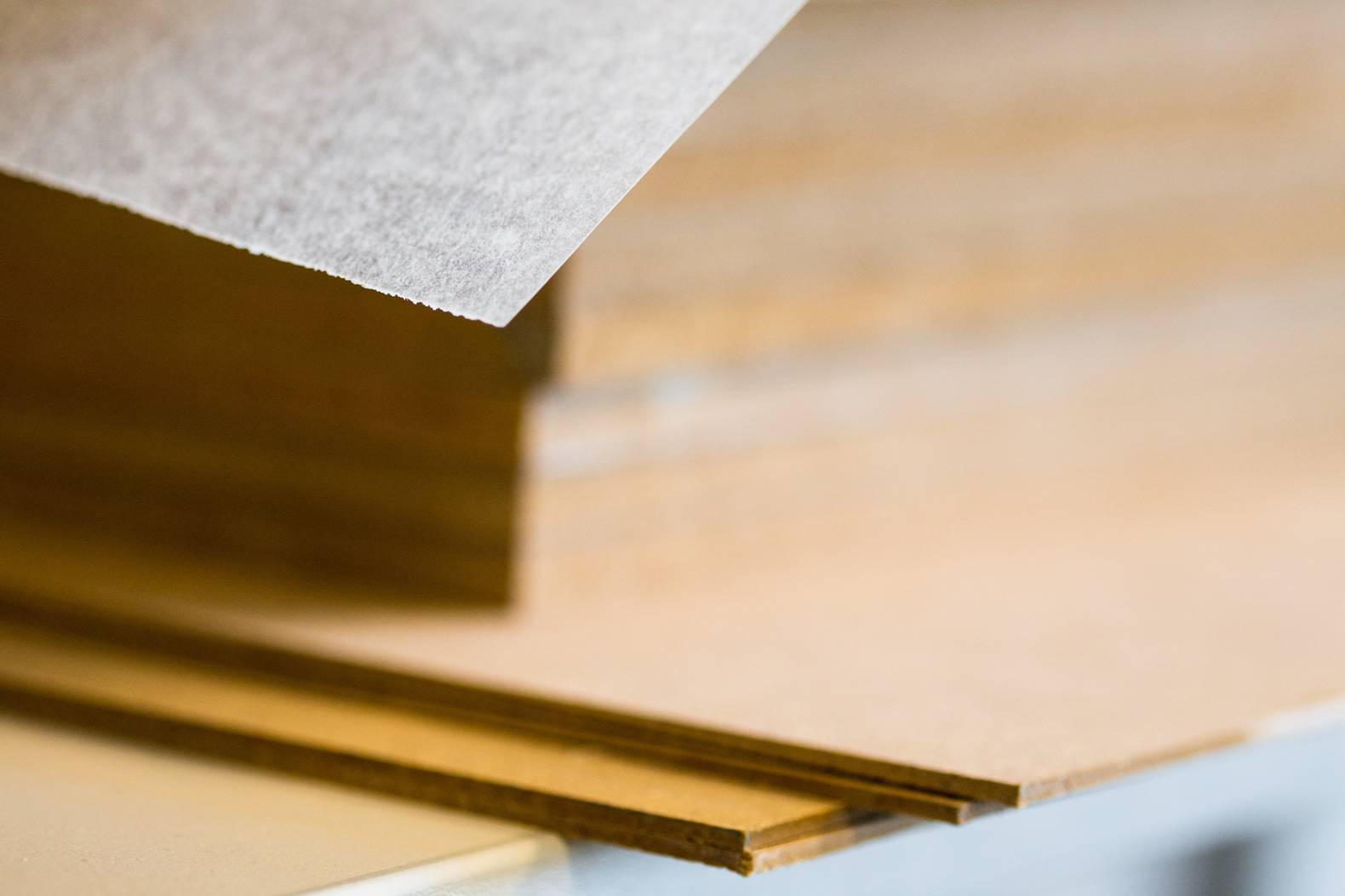

Decorative melamine based surfaces are used in the furniture and flooring industry. In principle the first production step is impregnation of decorative papers with a succeeding drying step. Afterwards the semi-finished product is pressed with heat and pressure on a wood based panel. The final surface properties are more or less fixed due to the resin and its behaviour during the impregnation step and the drying conditions at that time. During the first production step there is an interaction between the used paper and resin. Very important at that time is rapid and uniform resin uptake. Due to that, a faster and more economical production procedure is possible and the basis for further surface properties is established.

The better the impregnation process can be described, the more efficient it can be carried out. Therefore the knowledge of paper and resin properties in lab scale is a must to predict the interactions in production scale. The penetration time takes only a few milliseconds – so the characterisation possibilities are quite tricky.

With the, in the project established measuring method, the problems could be solved. The penetration behaviour could be described objectively for the first time. In the method, one makes use of the fact that the resin is electrically conductive. Due to the targeted application of the resin into the measuring system an objective measure of the paper saturation could be detected. This database makes it possible to target the resins properties to the adapted paper requirements and vice versa. Thus, correlations to the behaviour in the large-scale plant are possible and the opportunity to handle with otherwise non-processable papers is given.

The ideal resin content is realizable

A “normal” composite with impregnated paper is done like a sandwich “resin-paper-resin”. The paper is more or less only used to give an optical appearance to the final surface. It could be theoretically very thin and inexpensive. Unfortunately thin papers have the disadvantage of becoming curled during the impregnation step. Thus the resin application is unsymmetrical.

The results of the penetration measurement delivered data which better determined the impregnation characteristics of the paper. Due to that the company partner was able to install a modified application system and to impregnate curled and critical papers.

Impact and effects

A patent for this developed measuring method has been applied for.

In addition, the basic knowledge of resins and their characterization methods of penetration behaviour established in the COMET program, led to further research activities at the company’s partner.

As part of this work upscaling experiments were carried out to establish whether the impregnation of curled papers is possible.