Massivholz &

Holzverbundwerkstoffe

Forschungsinhalte

Der Bereich Massivholz und Holzverbundwerkstoffe beschäftigt sich mit der Neuentwicklung biobasierter Werkstoffe, unterschiedlichen holztechnologischen Prozessen sowie mit der Charakterisierung von Holz und Holzwerkstoffen und deren Anwendung in nachhaltigem Bauen und Möbeln. Die Widerstandsfähigkeit gegenüber negativen Auswirkungen von Feuchtigkeit und Nässe, die Feuerbeständigkeit und die Bedeutung von Emissionen aus Holzwerkstoffen werden eingehend untersucht und optimiert.

Da Klebstoffe eine wesentliche Rolle bei der Herstellung moderner Holzwerkstoffe spielen, sind ihre Synthese und Optimierung im Hinblick auf eine bessere Leistung und geringere Umweltauswirkungen weitere wichtige Forschungsschwerpunkte. Darüber hinaus werden die Wechselwirkungen zwischen Materialeigenschaften und technologischen Prozessen und Methoden untersucht, wobei Kreislaufführung und Digitalisierung eine wichtige Rolle spielen.

Unsere Forschungsthemen umfassen:

- Untersuchung und Optimierung von Zerteilungsvorgängen von Holzwerkstoffen und nachwachsenden Rohstoffen

- Trocknungstechnologie (Simulation und Optimieren der Industrietrocknung)

- Holz- und Fasermodifikation

- Oberflächenfunktionalisierung und Hydrophobierung

- Brandverhalten nachwachsender Rohstoffe

- Optimierte Herstellprozesse der Holzindustrie zur Verringerung der Produktvariabilität

- Entwicklung von neuen Bindemitteln

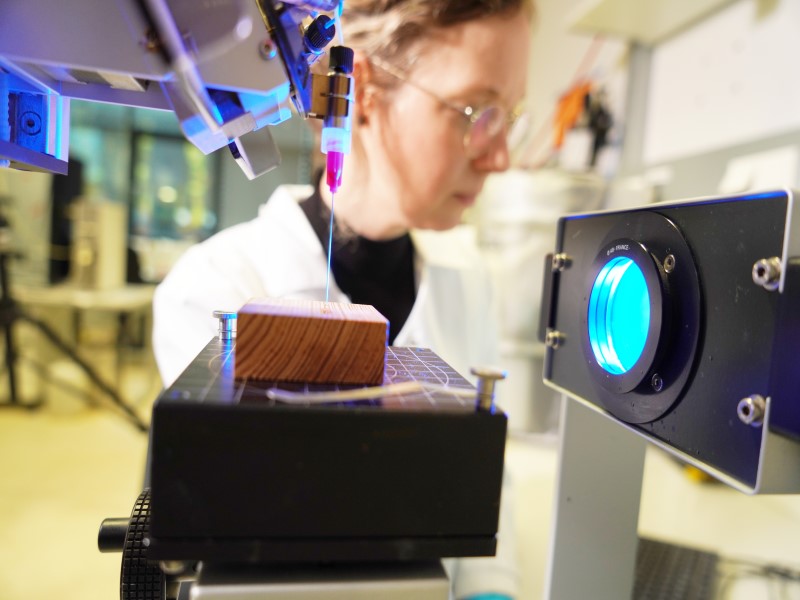

- Untersuchung von Bindemitteleigenschaften sowie Interaktionen zwischen Klebstoff und Holz

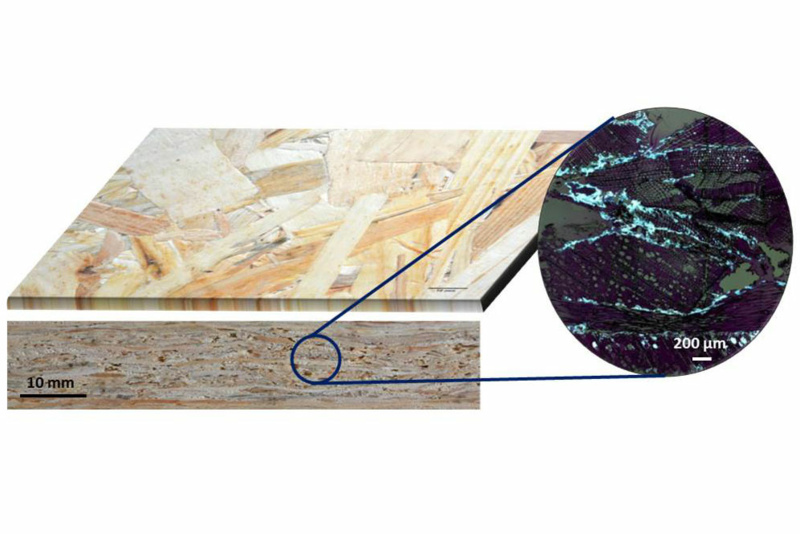

- Bindemittelverteilung an industriell gefertigten Holzwerkstoffen

- Analytik und Bewertung von VOC und Gerüchen aus Massivholz und Holzverbundwerkstoffen

- Entwicklung von Verfahren zur VOC- und Geruchsreduktion

- Funktionsorientierte Holzwerkstoffe mittels „Design Engineering“

Team Kreislaufgeführte Holzverarbeitungstechnologien

Im Team Kreislaufgeführte Holzverarbeitungstechnologien werden verschiedenste Technologien zur Zerteilung von Holz und verwandten Materialien beforscht. Unter dem Aspekt der Ressourceneffizienz sind vor allem Ausgangsmaterialien aus Abfallströmen und stofflich wenig genutzten Quellen von Interesse. Geschlossene Kreisläufe und ein adaptiertes Material- und Prozessverständnis führen zur Entwicklung von nachhaltigen Werkstoffen.

Team Funktionalisiertes Holz & biobasierte Materialien

Im Rahmen verschiedener Projekte beschäftigt sich das Team Funktionalisiertes Holz und biobasierte Materialien mit neuartigen Funktionalisierungsmethoden, die zu verbesserten Materialeigenschaften führen, insbesondere hinsichtlich Feuer- und Feuchtigkeitsbeständigkeit. Die Forschungsthemen reichen von hydrothermischen Behandlungen über verschiedene Funktionalisierungsmethoden bis hin zu porösen Strukturen und multifunktionalen Holzverbundwerkstoffen, wobei der Schwerpunkt auf möglichst bio-basierten Bauanwendungen liegt.

Team Neue Klebstofftechnologien

Die Verklebung ist die Basis aller Holzwerkstoffe, sie verleiht durch Adhäsion und Kohäsion allen Holzwerkstoffen mechanische Festigkeit. Das Team Neue Klebstofftechnologien untersucht Bindemitteleigenschaften und Bindemittelverteilung. Darüber hinaus werden neue Bindemittel, auch auf Basis von nachwachsenden Rohstoffen, und ideale Leimsysteme für neue Holzwerkstoffe entwickelt.

Team Digitale Technologien & nachhaltiges Bauen

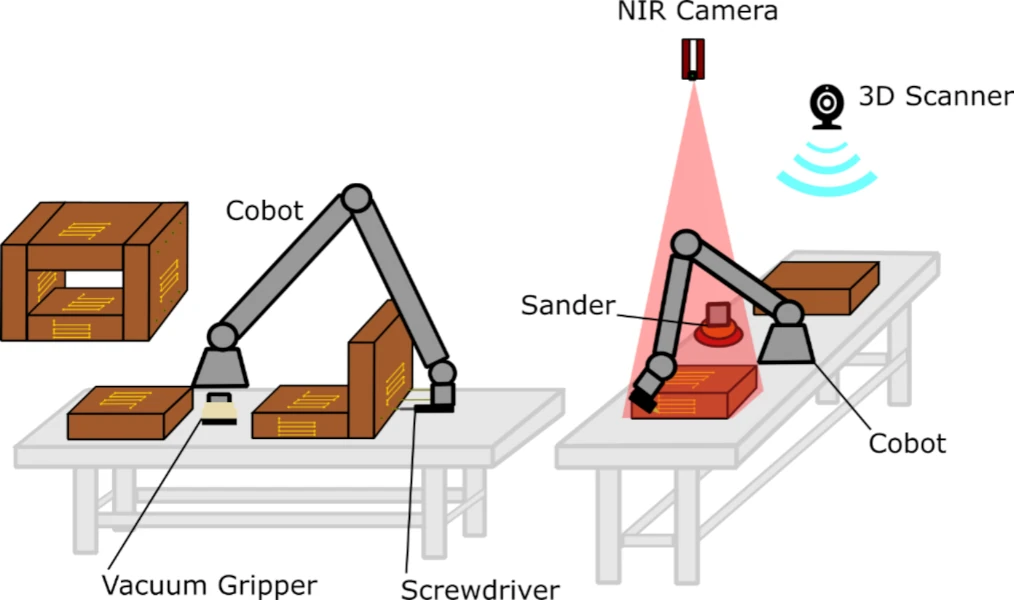

Das Team Digitale Technologien & Nachhaltiges Bauen befasst sich mit aktuellen Forschungsfragen zu neuesten digitalen Technologien und Methoden für Holzbe- und Holzverarbeitungsprozessen sowie mit Fragestellungen zu innovativen biogenen Materialien für nachhaltiges Bauen. Hier kommen bspw. Sensoren, Assistenzsysteme, Robotik, Akustik, machine learning, computer vision oder KI zum Einsatz. Mit Hilfe dieser Methoden werden Forschungsfragen zu innovativer Sensorik im Holzbau, zur Rückverfolgbarkeit von Holz entlang der Wertschöpfungskette, zur Prozessüberwachung und -modellierung oder zur Simulation von Holz-hybrid Bauelementen mit dem Ziel verfolgt, die Kreislauffähigkeit von Holz und nachwachsenden Rohstoffen im Bauwesen zu verlängern.

Team Materialemissionen – Analytik & Kontrolle

Das Team Materialemissionen – Analytik & Kontrolle beschäftigt sich mit der Methodenentwicklung, Analytik und Bewertung von VOC und Formaldehyd aus Holzverbundwerkstoffen und Holzprodukten, sowie mit Technologien zur Verringerung von unerwünschten Emissionen und Gerüchen aus Holzrohmaterial für Holzwerkstoffe und Holzprodukte durch mikrobielle Modifikation. Ein weiterer Forschungsschwerpunkt des Teams ist auch die Nutzung der Wachstumseigenschaften von filamentösen Pilzen, z.B. für die Herstellung von Mycomaterialien.

Ausstattung und Methoden

Im Bereich Massivholz und Holzverbundwerkstoffe können Entwicklungen und Untersuchungen vom Labor- bis hin zum Technikums-Maßstab mit eigenem Equipment realisiert werden. Darüber hinaus besteht durch die Kooperationen mit der BOKU Wien und der TU Wien Zugang zu modernster Infrastruktur in der Holz- und Naturfasercharakterisierung und -verarbeitung. In der Technikumshalle können neben diversen Versuchsaufbauten auf 450 m² auch Pilotanlagen betrieben werden.

PILOT- UND TECHNIKUMSANLAGEN

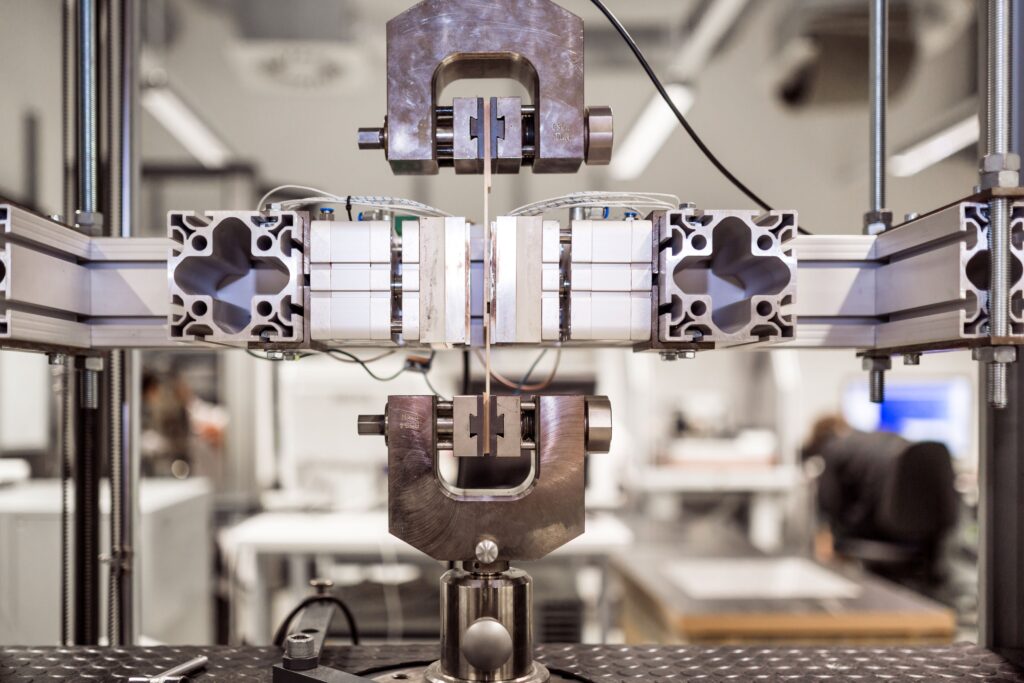

ANALYSE VON ZERTEILUNGSPROZESSEN

- 12“ Laborrefiner I Kochkessel

- Leistungsmessung I 4-Kanal

- Dreiachsige Schnittkraftmessung

- Hochgeschwindigkeitskamera

- Vollausgestattete Tischler- und Metallwerkstatt

HOLZTROCKNUNG UND HOLZMODIFIKATION

- Labortrockner I Frischluft – Abluft – Niedertemperatur – Dämpfen

- Hochtemperatur-Trockenkammer

- Vakuum-Trockenkammer

- Hochfrequenz-Vakuum-Trockenkammer

- Autoklav I Imprägnierung – hydrothermische Modifikation

- Chemische Modifizierung I Funktionalisierung

HOLZVERBUNDWERKSTOFFE

- Spänetrockner

- Vibrationssiebmaschinen

- Beleimmischer I Airlessbeleimsystem – druckluftbetriebene Sprüheinheit

- Laborheizpressen

- Multivariate statistische Modellierung von Prozessen

- Bildanalytische Charakterisierung der Partikelmorphologie

- Brandstand I Prüfung von Bodenbelägen

- Mini-SBI I downscaled single burning item test

PROTOTYPENBAU

- Vollausgestattete Tischlerwerkstatt I Kreissägen – Bandsäge – Tischfräse – Abricht- und Dickenhobelmaschine – Breitband- und Langbandschleifmaschine – CNC

- Metallwerkstatt I Drehbank – Fräse

- 3D Druck (kontinuierlicher Drucker, unabhängiger dual Extruder Drucker

PRÜFRÄUME / LABORS

PHYSIKALISCHE UND MECHANISCHE ANALYSEN

- Mechanische Analysen I Zug – Druck – Biegung – Schub – Brucharbeit, Schraubenauszug – Härte – ABES – Schlagpendel – Nanoindenter – DIC – 2D & 3D Deformationsmessung

- Klimakammern

- Wärmeleitfähigkeitsmessgeräte I λ-Meter – mini-λ-Meter – Wärme- und Feuchtedurchgangsbestimmung

- Bewitterungsstände I Schnellbewitterung – Freilandbewitterung

CHEMISCHES LABOR

- Bindemittelsynthese

- Thermische Analysen I DSC – DMA – TG – STA

- Spektroskopische Analysen I ATR/FTIR – NIR – UV/VIS – Raman

- Chromatographie I HPLC/DAD – RID – FLD – GC/FID – GC/MS SPME – TDA – Headspace

- Rheologie I Rheometer – Cold-Tack-Test

- Muffelofen

- Oberflächenanalyse I Kontaktwinkelmessgerät – Spektralphotometer – Chroma-Meter – Tastschnittmessgerät

- Extraktionen I Pressurized solvent extraction – Soxhlett – Autotitration

MIKROSKOPISCHE METHODEN

- Mikroskopische Analysen I AFM – UV/VIS – Fluoreszenzmikroskopie – Auflicht- und Durchlichtmikroskopie – Digitalmikroskopie – Bildanalytik

- Präparationstechniken I Schlitten- und Rotationsmikrotom – Ultracut – Färbetechniken

- Elektronenmikroskopie I ESEM – SEM – EDX

MIKROBIOLOGISCHES LABOR

- Dauerhaftigkeitsuntersuchungen I Holzschutzwirkung gegenüber Mikroorganismen

- Isolierung und Bestimmung von Mikroorganismen

- Kultivierung von Mikroorganismen I Großschüttler – instrumentierte Fermenter –Sterilwerkbank Klasse I

EMISSIONSMESSUNGEN

- Emissionsmessungen I Mikrokammern – 225 l Prüfkammern – 30 m³ Modellraum

- Humansensorische Analytik I Sniffing Panel – Geruchsstoffdarbietung – GC-O

DIGIWOODLAB

METHODEN

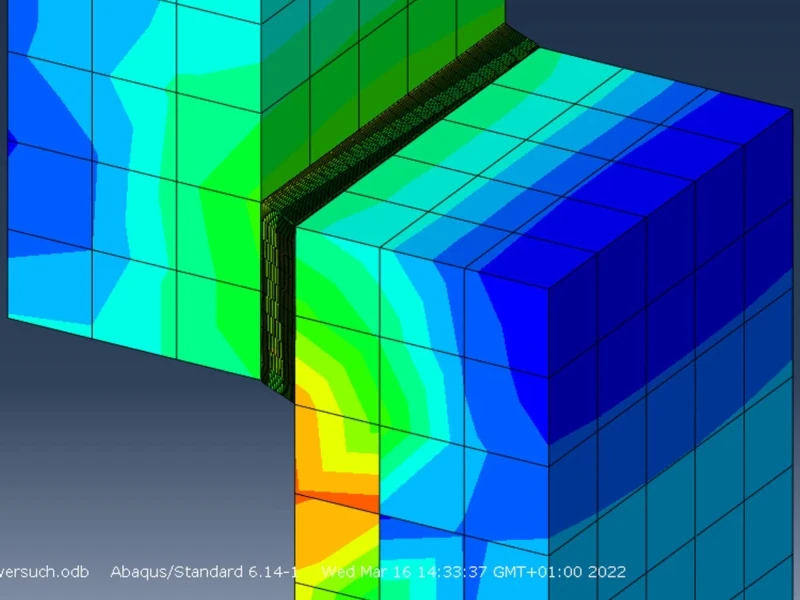

- Machine Learning | Deep Learning | Computer Vision | automatisierte Bildanalyse | Mustererkennung | Materialklassifizierung | Assistenzsysteme | Signalanalyse (FFT, etc.) | Prozessmodellierung (Big Data, Datenqualitätsanalyse, Datenfusionierung, multivariate statistische Modellierung, Qualitätsvorhersage) | statistisch-physikalische Modellierung | Finite Element Modellierung | statistische Versuchsplanung

HARDWARE

- 3 kollaborative Roboter (Cobots) inkl. diverser Endeffektoren (Greifer, Schleifer, Schrauber, Dosiereinheit, 3D Scanner, Kameras) | Roboter-Linearachse | NIR-Hyperspektralkamera inkl. Laborstation | Lasercutter | zwei 3D Scanner | Spatial Augmented Reality Assistance System | wearables (Augmented Reality Brille, Virtual Reality Brille, intelligenter Gehörschutz) | diverse Kameras (360°, robuste, hochauflösende, etc.) | Luftschallsensoren (robust und optisch bis 1 MHz) | Körperschallsensoren | zwei leistungsstarke Workstations | diverse Peripherie wie z.B. Mikrocontroller oder Raspberry Pis

SOFTWARE

- Abaqus | MATLAB (inkl. Compiler) | Python | R | SQL | Solid Works | Design Experts | RoboDK | Unity | Vuforia

Ansprechpartner

im Bereich Massivholz & Holzverbundwerkstoffe

DI Dr. Christian Hansmann

Bereichsleitung

Key Researcher

DI Dr. Erik van Herwijnen

Bereichsleitung Stellvertretung

Teamleitung Neue Klebstofftechnologien

DI Dr. Stefan Pinkl

Teamleitung

Kreislaufgeführte Holzverarbeitungstechnologien

Mag.a Dr.in Cornelia

Rieder-Gradinger

Teamleitung

Materialemissionen – Analytik & Kontrolle

DI Dr. Martin Riegler

Teamleitung

Digitale Technologien & Nachhaltiges Bauen

DI Dr. Axel Solt-Rindler

Teamleitung

Funktionalisiertes Holz und biobasierte Materialien

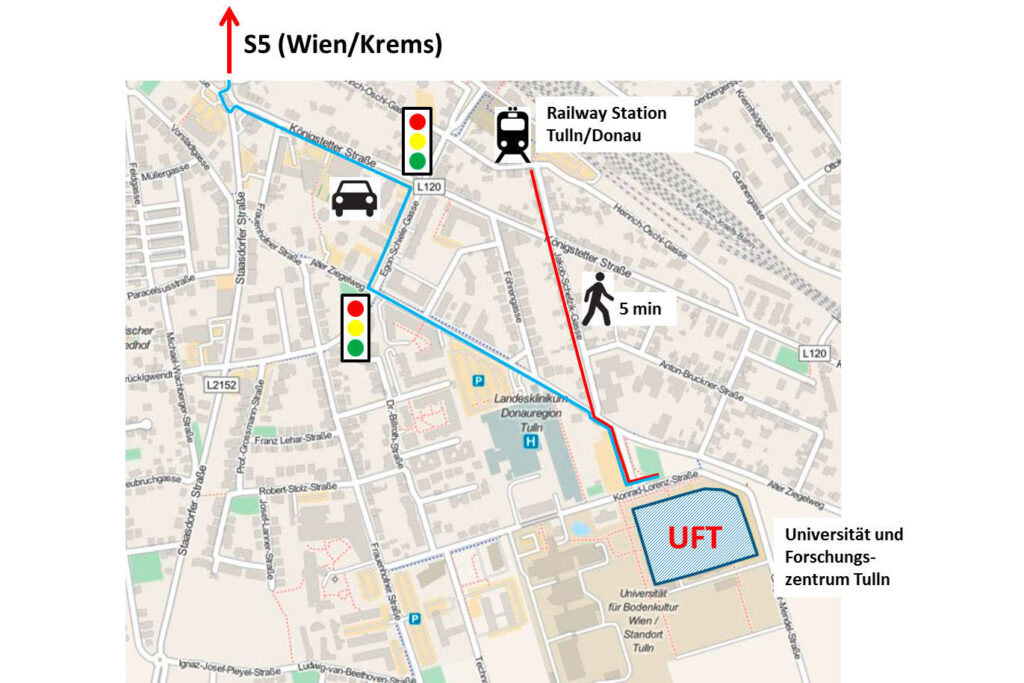

Kontakt und Anfahrtsplan

Adresse

Kompetenzzentrum Holz GmbH

Bereich Massivholz & Holzverbundwerkstoffe

c/o UFT Universitäts- und Forschungszentrum Tulln

Konrad-Lorenz-Straße 24

3430 Tulln/Donau

Der Bereich Massivholz und Holzverbundwerkstoffe (abgesehen von der Arbeitsgruppe Holzbiotechnologie, TU Wien) ist am Institut für Holztechnologie und Nachwachsende Rohstoffe, Department für Materialwissenschaften und Prozesstechnik, BOKU Wien am Standort Tulln.

Die BOKU ist am Campus Tulln im s.g. UFT (Universitäts- und Forschungszentrum Tulln), Konrad-Lorenz-Straße 24, A-3430 Tulln untergebracht. Die Räumlichkeiten von Wood K plus liegen im (südlichen) hinteren Gebäudeteil im 1. Stock. Über den Haupteingang durch die Aula bis zum hinteren Stiegenhaus, 1. Stock rechter Flügel, beginnend bei Büro Tür Nr. 1.3.119.

Mit dem Auto

Von der Westautobahn kommend (A1) bis St. Pölten – S33 Richtung Krems – bei Traismauer S33 folgend Richtung Tulln/Wien bis Tulln.

Von der Südautobahn kommend (A2) Richtung Zentrum – Südosttangente (A23) bis Knoten Kaisermühlen – Richtung Krems auf Donauufer Autobahn (A22) – bei Stockerau gerade weiter Richtung Krems auf S5 bis Tulln.

Mit öffentlichen Verkehrsmitteln

Bahn (Station Wien Franz Josefs Bahnhof, Wien Spittelau oder Wien Heiligenstadt jeweils Stationen der U-Bahn U4) bis Bahnhof Tulln. Über die Bahnhofstraße in die Jakob-Schefzik-Gasse bis direkt vor das UFT (ca. 7 min. Fußweg).

Vom Westbahnhof U-Bahn U6 Richtung Floridsdorf bis Station Spittelau (weiter siehe oben).

Vom Südbahnhof U-Bahn U1 Richtung Leopoldau bis Station Schwedenplatz, Umsteigen in U-Bahn U4 Richtung Heiligenstadt bis Stadion Spittelau (weiter siehe oben).

Über den Luftweg und öffentliche Verkehrsmittel

Flughafen Schwechat – City Airport Train (CAT) bis U-Bahnstation Wien Mitte (U3, U4), Umsteigen in die U-Bahn U4 (Richtung Heiligenstadt) bis zur Endstation Heiligenstadt (weiter siehe oben).