Accompanying environmental and techno-economic assessments of lignin-based resins during the innovation process

The accompanying assessments of bio-based products during the innovation process by considering environmental and techno-economic aspects supports the implementation of these products on the market. Barriers regarding the use of lignin-based resins are mostly linked to technical and economic issues, whereas the incentives are based on the expected lower environmental impacts of the lignin-based resins compared to the conventional resins. The environmental assessment conducted within the study emphasis this incentive.

Valorisation of the by-product lignin

In line with a resource efficient and sustainable use of the raw material wood the valorisation of side streams from pulp and paper industry is currently part of many research agendas. One possibility of valorisation is the use of the by-product lignin as substitute for phenol in phenol-formaldehyde (PF) resins in wood-based panels.

The aim of this study was an iterative environmental and techno-economic assessment of the substitution effect of lignin in PF resins. Lignin-based PF (LPF) resins are currently in lab scale. In order to support the further development of LPF resins the identification of potential barriers and incentives of the market, as well as the assessment of the global warming potential (GWP) in comparison with conventional PF resins is of interest. Due to the accompanying assessments the innovation process is guided towards sustainable and competitive products.

Assessment of LPF resins during the innovation process

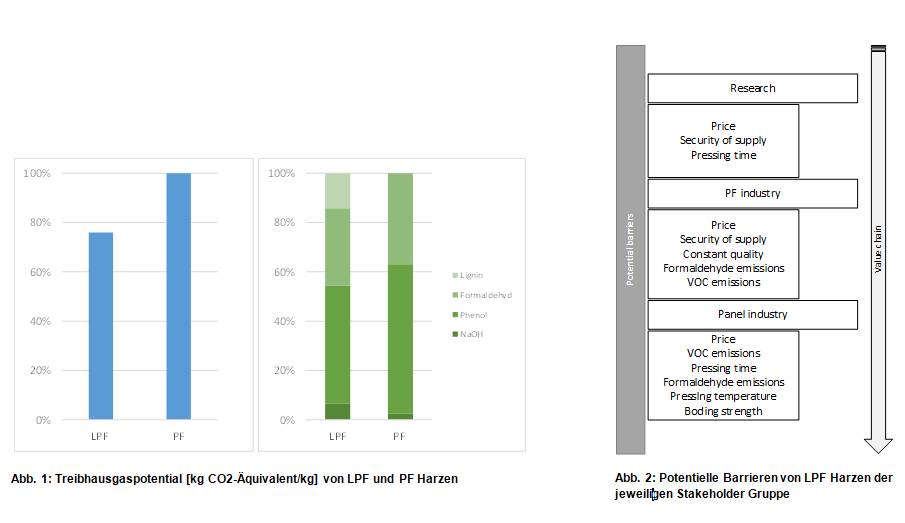

Figure 1 shows the results of the comparative assessment for LPF resins and conventional PF resins regarding the global warming potential. Due to the partial substitution of the fossil oil based phenol by lignin the global warming potential, given in CO2-equivalents/kg, of LPF resins is 22% below the conventional PF resins. Additionally a hot-spot analysis was carried out in order to show the contribution of the inputs to the total global warming potential. The hot-spot analysis revealed that the phenol hast the biggest contributor. Within the diffusion on an innovation – from lab to the market – numerous barriers that need to be overcome, as well a potential incentives, which might support the implementation of the new product, should be identified.

An essential element of the accompanying techno-economic assessment is the integration of various stakeholder groups along the innovation-value chain:

From the research and development to the industrial production and implementation in wood-based panels. Thereafter the conducted study included experts from the stakeholder groups: Research, PF industry and panel industry. Potential barriers derived from the study are shown in figure 2. For further research and development the knowledge on potential barriers (e.g. expected technical and economical characteristics) of potential adopters is of great importance. Potential incentives are mostly given for the expected lower environmental impacts of LPF resins compared to their conventional counterparts. This incentives could be verified by the environmental assessment conducted within the study.

Impact and effects

By accompanying the innovation process of bio-based products it is possible to iteratively integrate environmental as well as technical and economic aspects into the development.

The conducted study showed that the early integration of environmental and techno-economic assessment, considering various stakeholder groups, supports the entire innovation process. The results shown within this study can be integrated directly into the further development of LPF resins. On one side the study supports the efficient use of raw materials. On the other side the results supports the entire innovation process by showing potential barriers which need to be overcome in order to implement LPF resins.