Mathematical model provides insight into gluing of wood particles

By combining two mathematical modelling methods, unobserved phenomenons during gluing of wood particles could be described and simulated.

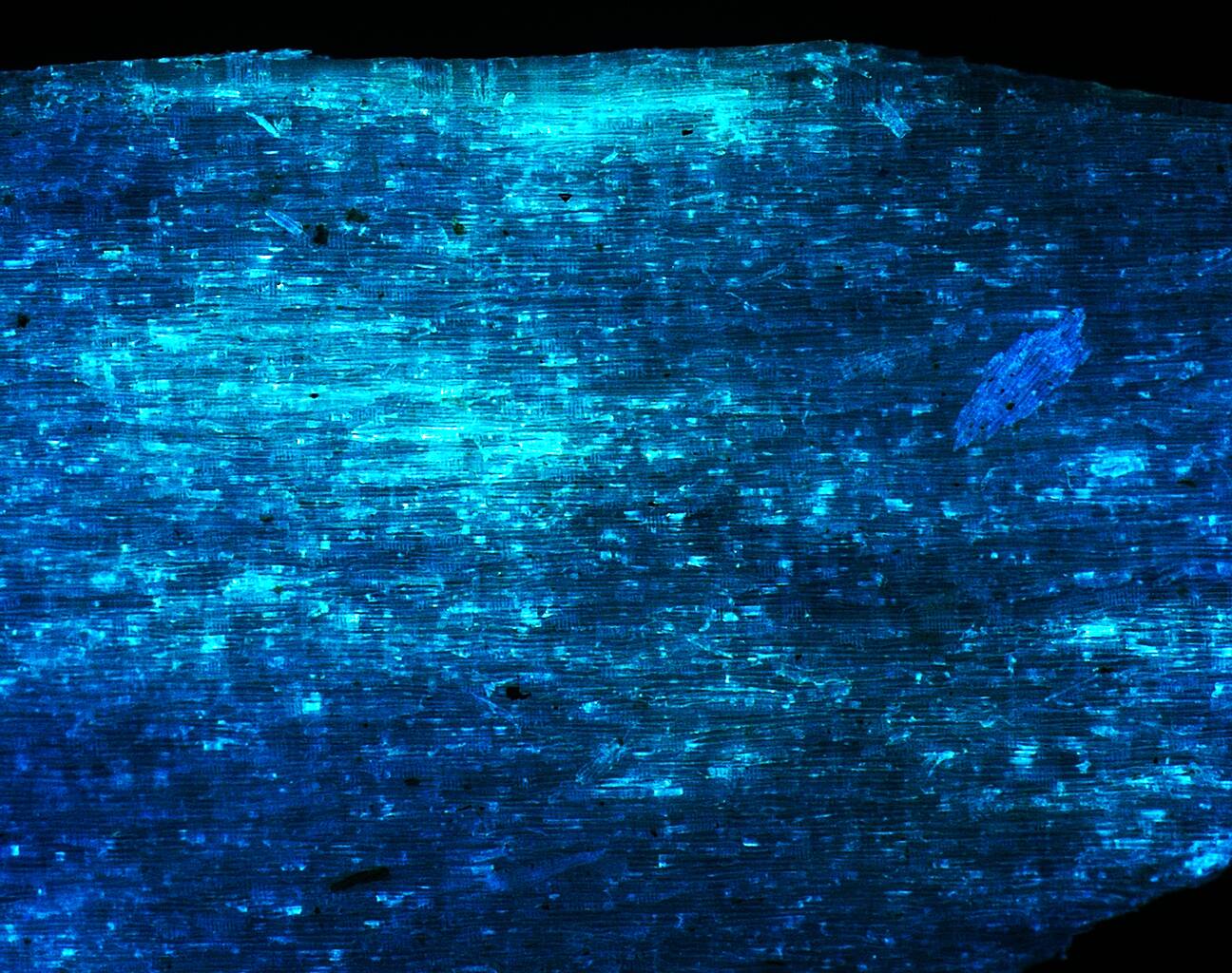

Particleboards consist of small wood particles that are glued with synthetic adhesives. Although this product exists since several decades, the gluing process is still a black box. Literature suggests providing small adhesive droplets to be applied onto the surface of particles to reach a uniform distribution of adhesive. However, researchers are divided over the optimum properties of adhesive droplets or the effects of varying wood particle properties.

The main reasons for this lack of knowledge are challenges in the setup of real-life experiments. In especially, challenges are to place adequate sensors in the gluing zone, to obtain defined and reproducible particle properties and to characterise thousands of particles at a microscopic level.

In such situations, computer simulations based on detailed mathematical models often find a remedy. In the course of the dissertation entitled “Modelling Synthesis of Lattice Gas Cellular Automata and of Random Walk and Application to Gluing of Bulk Material”, a mathematical model and simulation for the gluing of wood particles was developed. The aim was to obtain a better understanding of the gluing process. Thus, the behavior and collision of wood particles and adhesive droplets was described to obtain the resulting adhesive distribution on the surface of wood particles. For developing a mathematical model, the modelling methods “Lattice Gas Cellular Automata” and “Random Walk” were used. The model was implemented in MATLAB and different scenarios were simulated to investigate the effects of a mixing arm, realistic size distributions of wood particles and adhesive droplets, the transfer of adhesive between wood particles and the total mass of adhesive. Furthermore, the results were compared with experimental measurements.

In the simulation, an inhomogeneous size distribution of wood particles led to a higher variation in resin coverage and diameter of adhesive areas on the surface of wood particles. The transfer of adhesive between wood particles due to mixing accelerated the gluing of particles by about one third. The total mass of adhesive applied in the simulation correlated linearly with the mean coverage of wood particles with adhesive. Compared to experimental results, this first simulation showed similar mean coverage values.

Impact and effects

The simulation results show that the mathematical model is feasible for studying the gluing of wood particles. In especially, effects that can hardly be tested in real-life experiments have the highest potential to be investigated by the simulation. This leads to an optimization of gluing wood particles in terms of machine construction & configuration, adhesive properties or optimal shape and size of wood particles. Consequently, knowledge is gained to increase resource efficiency at the industrial manufacturing process of particleboards.