Molecular Dynamics Simulation (MDS) for bio-based thermosetting resins

The main goal was to investigate the extent to which material development of thermosetting resin systems based on renewable raw materials can be accelerated with the help of computer-aided molecular dynamics (MD) simulation. In this project, we adopted a novel molecular simulation technique to track the polymerization of an epoxy resin cross-linked with an acid anhydride hardener.

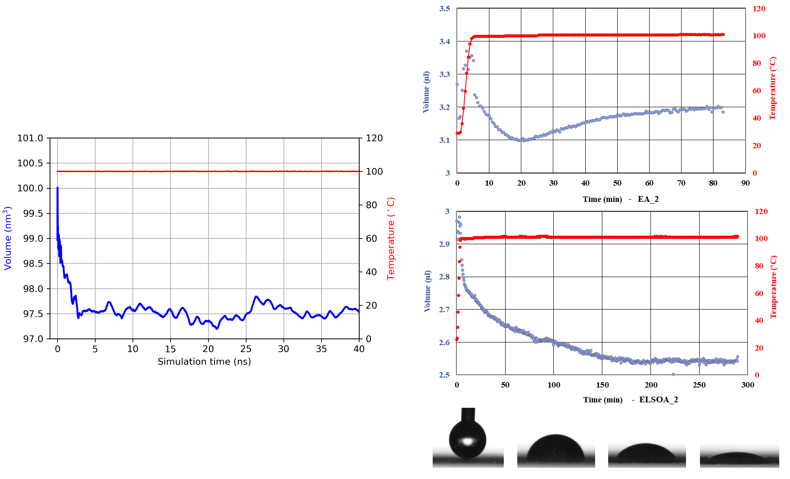

We studied the polymerization of two epoxy resins, a bio-based epoxidized vegetable oil, and a standard bisphenol A based epoxy resin, cross-linked at 100°C with an acid anhydride hardener (Figure 1), in both laboratory experiments and molecular simulations. In particular, we used a simulation technique that, unlike ordinary classical molecular simulations, allows two molecules to connect (react) within a given distance and probability.

The particular distance and probability are adjustable parameters that were fitted to replicate the same volume changes during polymerization as in experiments. The cure shrinkage was determined experimentally using an adapted method to measure contact angle values (Figure 2).

This novel work on renewable materials demonstrates that molecular simulations, when parameters are properly adjusted, can generate realistic polymer models on which (thermo)-mechanical properties such as glass transition temperature, cure shrinkage, and elastic modulus can be computed. The presented technique is capable of computationally testing novel, not yet synthesized polymer formulations as a pre-screening tool and could potentially guide the discovery of new performant polymeric systems.

Funding programme: EFRE - Regionale Impulsförderung

Duration: 09/2021 – 03/2023

Consortium: Alpen-Adria-Universität Klagenfurt, Wood K plus (Lead)

Contact: Günter Wuzella (g.wuzella@wood-kplus.at)

Acknowledgements: Area 3 Laboratory team for Characterization and Testing