Statistical design of experiments for knowledge-based production

The aim of the project was to map the curing behaviour of different adhesives in laminates and thus to optimise the manufacturing conditions.

Statistical Design of Experiments (DoE)

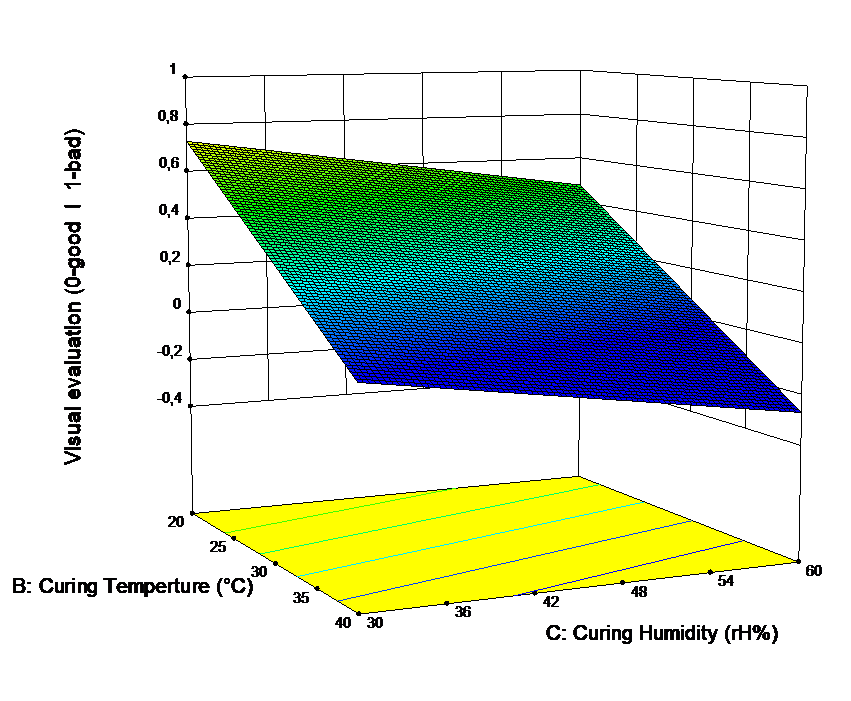

Statistical test planning enables optimised test processing with the objective to find out which process parameters have which influence on defined target variables. In this way, a tool – statistical design of experiment – is used that makes it possible to identify causality behind a change in product quality with a minimum of effort. In this specific case, the influence of temperature, curing moisture and storage moisture on the final product quality of a laminate was investigated. With the selection of the factors, the seasonal variations in manufacturing process were simulated. By using technological values of layer adhesion and quantitative determination of bubble formation, response surface models could be created with the aim to get mathematical models for process optimisation. The characterisation was supplemented by spectroscopic investigations to clarify the curing kinetics and the associated reaction time shifts.

Predictive models - for robust production-related environments

With the systematic test evaluation, the significant influencing factors for the seasonal manufacturing fluctuations could be identified. Optimised curing processes for the individual adhesive systems were derived from this, which can now be controlled to suit the prevailing environmental conditions so that the laminates are fully cured after a defined curing time and do not show any bubble formation in the temperature shock test.

Especially for the readjustment of the "winter settings", it can be stated that there is a clear correlation between ambient temperature and humidity during adhesive processing with the duration of the curing time and bubble formation for the adhesive systems, and that this is significantly prolonged compared to summer.

Effects and impacts

The created models serve as a further piece of the puzzle for the company partner to be able to manage the production processes in an optimised manner. Showing interactions between used adhesives and seasonal production fluctuations, as well as the resulting optimisation potential of the storage conditions, prove that the explained approach of DoE can provide the basis for knowledge-based production. This concept is an important building block on the way to Industrie 4.0.