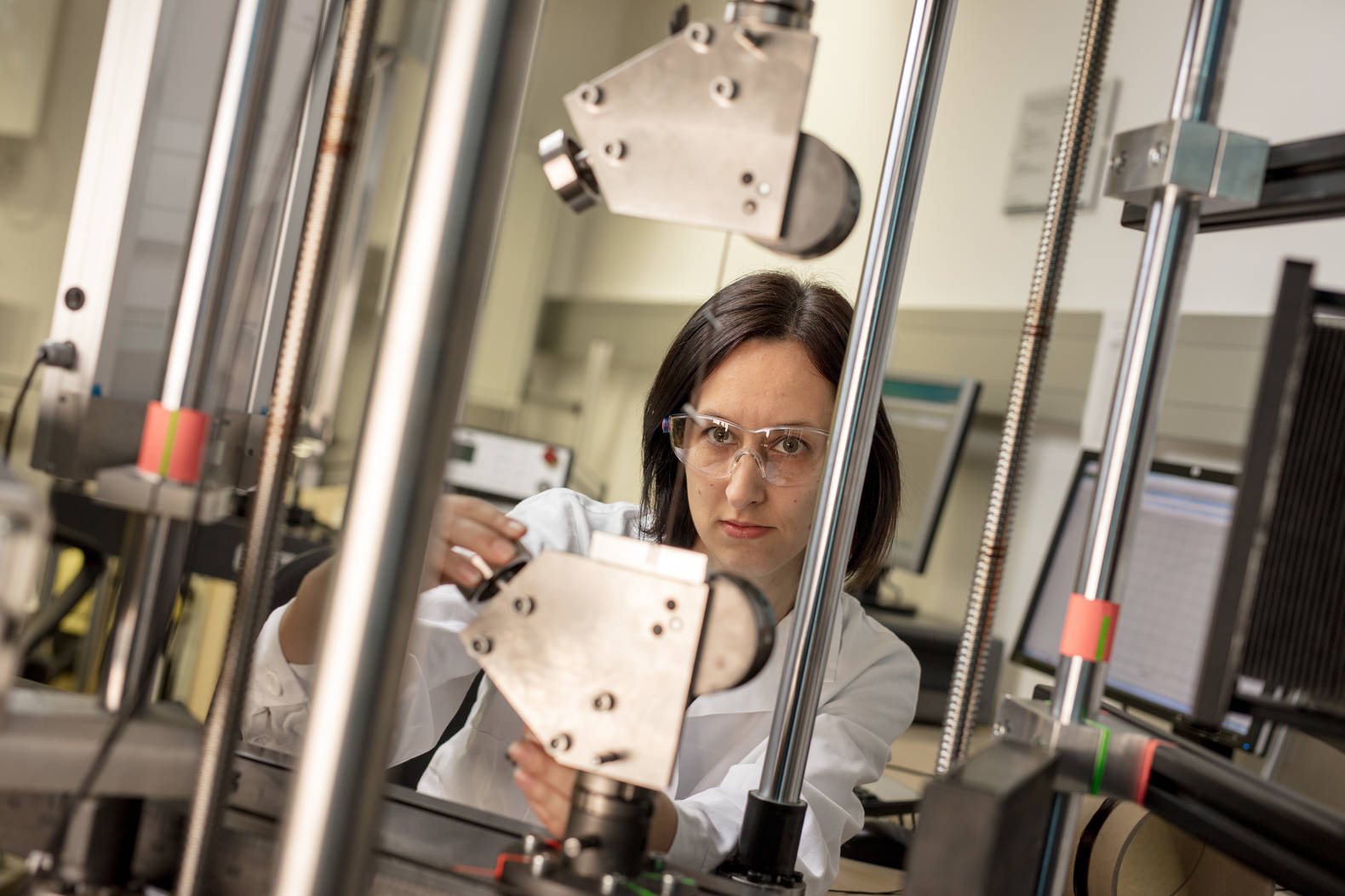

Equipment and Methods

In the Biobased Composites & Processes division, R&D projects from the lab- up to the pilot plant scale can be realised using own equipment. In addition, equipment of the JKU is available via various joint projects.

Pilot plant scale equipment

Extrusion/Compounding

-

WPC/NFC extrusion line Cincinnati Fiberex K38 (6-fold gravimetric dosing)

-

Co-extruder CE 42

-

Chemical foaming

-

Filament production for 3D-FLM printing (short and continuous fiber reinforced polymers)

-

Multifilament melt spinning line FET (0,8 – 3,0 kg/h, max. 2000 m/min)

-

Various extrusions tools, including slit die rheometry

-

Brabender DSE 20/40 (5-fold gravimetric dosing)

-

Brabender KDSE 32

-

Hot die face pelletizing system Erema KG 80

-

Under water granulation system Econ EUP 50

-

Strand granulation system RIETER Primo 50

-

Henschel heating/cooling mixer FML 10 / KM 23 (10 L)

-

Rhönrad mixer

Injection molding

-

Wittmann-Battenfeld SMARTPOWER 120/350 UNILOG B8 (equipped for thermoplastics and thermosets)

-

Dryer Wittmann-Battenfeld Drymax Aton2 F 120 kompakt (4 x 30 L, 1 x 50 L)

- Various tools for specimens, plates, determination of flow distance, so

3D printing

-

FLM printer German RepRap X400 PRO V3 (build area 390 x 400 x 330 mm)

-

FLM printer Original Prusa i3 MK3S incl. Multi Material 2S upgrade kit

-

3D scanner Steinbichler COMET LƎD 5M (measuring fields: 45-500 mm, resolution: 5 megapixel, max. accuracy: 18 µm)

High temperature equipment

- High temperature chamber furnace (2,300 °C max., usable volume 6 L)

-

Chamber furnace (900 °C max., usable volume 150 L)

-

Rotary furnace (1,100 °C max.)

-

Tube for furnace for oxidation/stabilisation (300 °C max., 5 heating zones each 50 cm)

-

Tube for furnace for LT carbonisation (1,050 °C max., 5 heating zones each 50 cm)

-

Tube for furnace for HT carbonisation (1,700 °C max., 2 heating zones each 50 cm)

Material testing / Lab equipment

-

Laboratory press (320 x 320 x 200 mm)

-

Thermal analysis (DSC: OIT, High pressure pan, Rapid Cooling; HDT-A/B/C)

-

Optical analysis (microscopy, REM, XPS)

-

Pore analysis (gas adsorption, Hg porosimeter)

-

Mechanical testing (tensile, flexural, compression, impact, falling ball test)

-

Spun yarn/multifilament-tensile testing

-

Fiber/filler characterisation (sieve analysis, bulk density, fiber length distribution by FASEP)

-

Soxhlet-Extraction

-

Rheology (dynamic rheometer Anton Paar MCR 102; MFR – melt mass-flow rate)

-

Chemistry lab, incl. fume cupboard

-

Fire testing (single-flame source test, UL 94, building materials following DIN 4102-1)

-

Dielectric analysis (curing analytics for thermosets)

-

Tensiometer for contact angle and surface energy determination (Krüss K100)

-

Ash content determination (rapid incinerator, muffle furnace)

-

Quantitative determination of inorganic fillers and reinforcing materials, respectively, by incineration in muffle furnace

-

Electro-acoustic spectrometer DT1200 for particle size distribution analysis

-

Artificial weathering (Xenon-weathering chambers)

-

Climate cabinets

-

High-voltage tester CEAST DIELECTRIC RIGIDITY

-

Several different saws and a CNC milling machine for sample preparation