Equipment and Methods

In the field of Smart Composites & Surfaces at our site in St. Veit an der Glan, we have excellent analytical methods specialized in the characterization of surfaces. This offer is rounded off by comprehensive laboratory and pilot plant equipment, as well as wet-chemical and climatic laboratory facilities. In addition, through the cooperation in our scientific and industrial network, there is access to further state-of-the-art infrastructure..

Material Characterisation

MICROSCOPIC METHODS

Microscopic Analyses I AFM – Fluorescence Microscopy – Reflected Light and Transmitted Light Microscopy – Digital Microscopy – Laser Scanning Microscopy

Image Analysis | 3D Surface Measurement – Surface Roughness, Waviness, Primary Profiles

Preparation techniques I Rotational and ultra-microtome – Dyeing techniques – Grinding and polishing techniques

SPECTROSCOPIC METHODS

MIR area I ATR/FTIR heat able– locally resolved – ad line – inline

NIR area I Diffuse Transmission – Diffuse Reflection – Directional Reflection – Hyperspectral Imaging

UVVIS area | Diffuse Transmission – Diffuse Reflection – Directional Reflection

Multivariate Spectra Analysis

THERMAL ANALYSES

DSC I specific heat capacity – crosslinking kinetics MFK

TGA with FTIR coupling I Mass degradation incl. identification of gases – content, moisture or solvent – Determination of thermal stability – Oxidation stability – Decomposition kinetics

TMA I thermal dimensional change – coefficient of expansion – swelling behaviour – glass transition temperature

PHYSICAL AND MECHANICAL ANALYSES

Mechanical analyses I Tension – Compression

Environmental simulation I fast weathering – outdoor weathering – climate testing

Rheologie

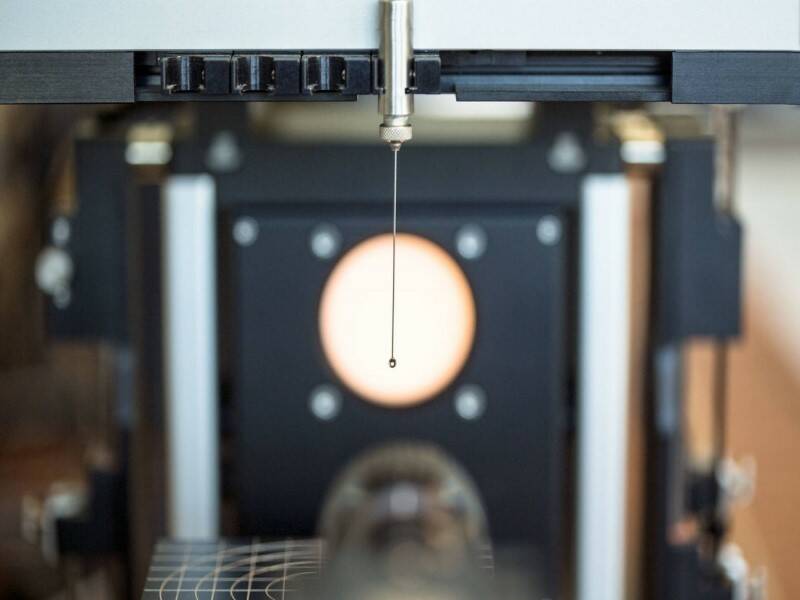

Tensiometry IContact angle | Surface Energy | Surface tension

Electroacoustic spectrometer for particle size analysis

Dielectric Analyses I Curing Kinetics

Surface testing of wood-based materials

Paper Exams | Formation Analysis – Penetration Behavior – Smoothness – Gurley

Moisture measurement I Water content measurement I Steam sorption measurement

Thermography | active and passive – monitoring and control of process temperatures – steady-state microthermography

Measurement data acquisition systems

DIGITAL TECHNOLOGIES & METHODS

Multivariate data analysis I Prime Component Analysis – Prime Component Regression – PLS Regression – Multiple Linear Regression – Cluster Analysis – Multivariate Curve Resolution

Multivariate Statistical Modelling I Finite Element Modelling

Statistical design of experiments I Design Experts

Pilot and pilot plants

COMPOSIT TECHNICUM

Up Scaling Batch Reactor 5 L

Laboratory foulard I Impregnation or dyeing of nonwovens, mats, textiles

Spray drying of polymer dispersions

LCM process

FEM Analyse Software I Pre- Post Processing – Simulation of fiber composite components

Deformation analysis with Auto Grid I optical

3D PRINTING

Desktop Continuous Fiber Printer | Glass – Aramid – Carbon in Polyamide Matrix

COATING TECHNOLOGIES

Heating Cooling Press 760 × 420 mm | Mould carrier press 600 × 600 mm

Atmospheric Pressure Plasma | Activation and coating

Powder coating | electrostatic infrared curing of natural fibre composites

MDF, natural fiber composites, metal, chipboard, WPC

UV polymerization of UV curing systems

Film applicators | Automated and manual