News

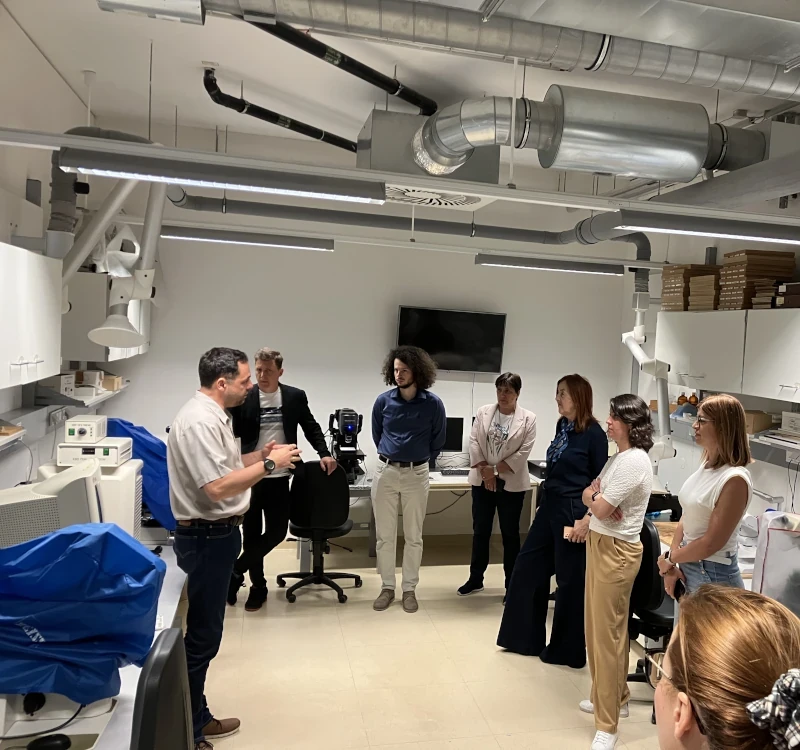

Vom 04. bis 05. Juni 2025 war das Konsortium von „RTIT>>“ zu Gast bei Wood K plus am Standort in Tulln, Österreich am Universitäts- und Forschungszentrum (UFT) der BOKU Universität ...

In der immer internationaler werdenden Forschungswelt ist interkulturelle Kompetenz nicht nur ein „Nice-to-have“, sondern eine entscheidende Zukunftskompetenz. ...

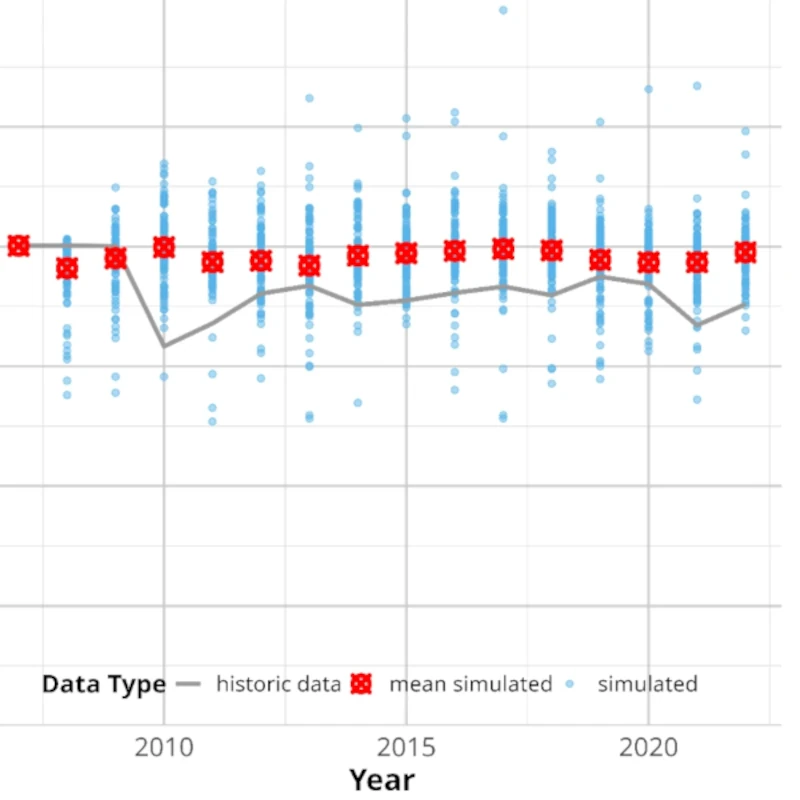

Internationale forstbasierte Lieferketten sind mit inhärenten Risiken und Ungewissheiten konfrontiert, die von verschiedenen Faktoren herrühren ...

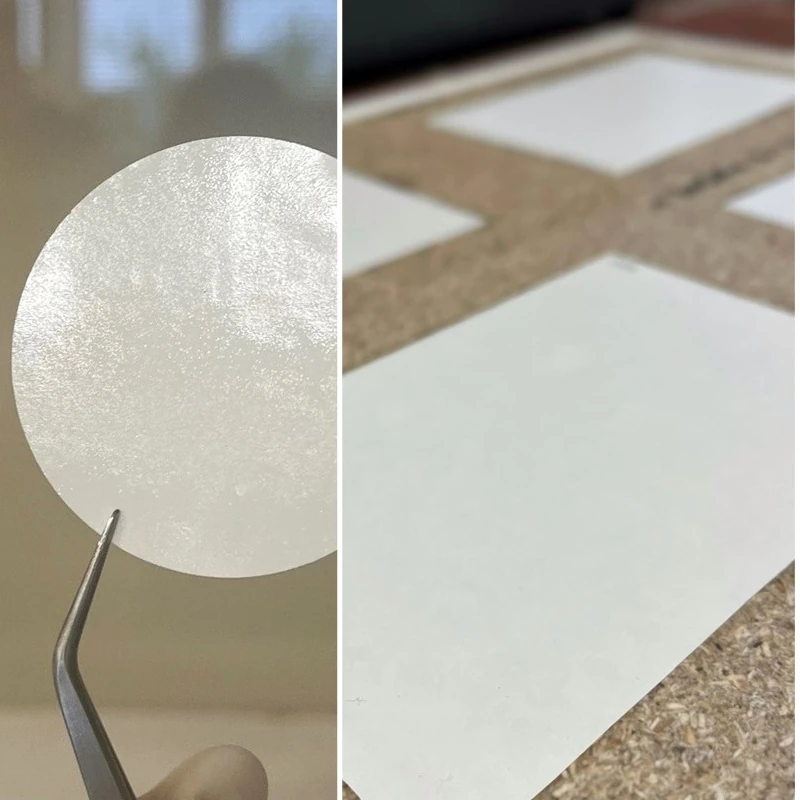

Dekorative Laminate sind aus der modernen Innenarchitektur nicht mehr wegzudenken – sie finden Anwendung in Möbeln, Fußböden und Wandverkleidungen. Mit dem wachsenden Fokus auf nachhaltige Materialien steigt auch der Bedarf ...

Wir freuen uns, dass unser Projekt WOOD4ALL als Best-Practice-Beispiel der HR-Excellence Initiative des UAR Innovation Networks mit einem LT1 Beitrag und einem Preisgeld von 10.000 € ausgezeichnet wurde! ...

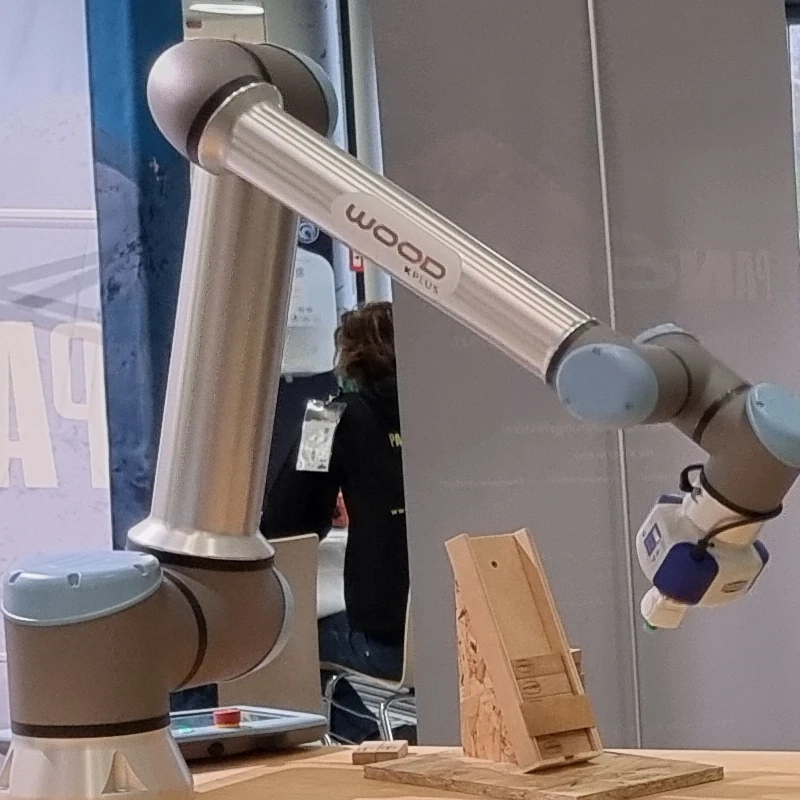

An unserem Standort Massivholz und Holzverbundwerkstoffe in Tulln wurde vor Kurzem eine einzigartige Forschungs-infrastruktur zu digitalen Technologien für die Holzforschung und intelligente Produktion von Biomaterialien und -strukturen eröffnet. Wood K ...

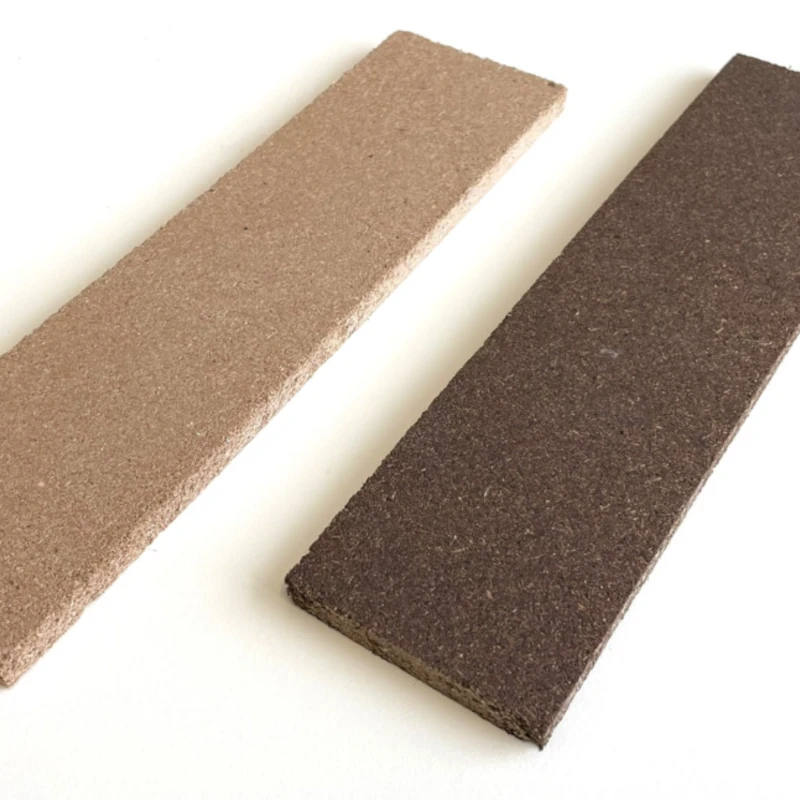

Neuartige 100% biobasierte Holzstaubwerkstoffplatte, herstellbar ohne Wasserzugabe und mittels konventioneller Fertigungsprozesse ...

Innovative Verwertung eines Bioraffinerienebenstroms für eine effizientere Nutzung des Rohstoffs Holz ...

Das Projekt: „Flexible Wood“ wurde zum Innovations- und Forschungspreis nominiert. ...

Es ist uns eine Ehre, dass unser Projekt WOOD4ALL im Rahmen der Initiative „HR-Excellence im UAR Innovation Network“ zu den prämierten Best Practice Beispielen gehört! ...

Entdecke die Höhepunkte des Wettbewerbs und lasse dich von unseren Gewinnern und ihren Use Cases inspirieren! ...

Vom 27. – 28.11.2024 durfte Wood K plus die PANORAMA 2024 - das Digitalisierungsfestival für Holz-, Forst-, Land- und Energiewirtschaft in Wels – mit veranstalten. ...

Der Podcast „I am Scientist“ von Daniel Hölle und Philipp Hubert thematisiert den Forschungsalltag junger Wissenschaftler*innen und ihren Weg zur Dissertation. ...