Invitation - Student Camp 2019

8.1.2019: Fully booked, Registration closed.

8.1.2019: Fully booked, Registration closed.

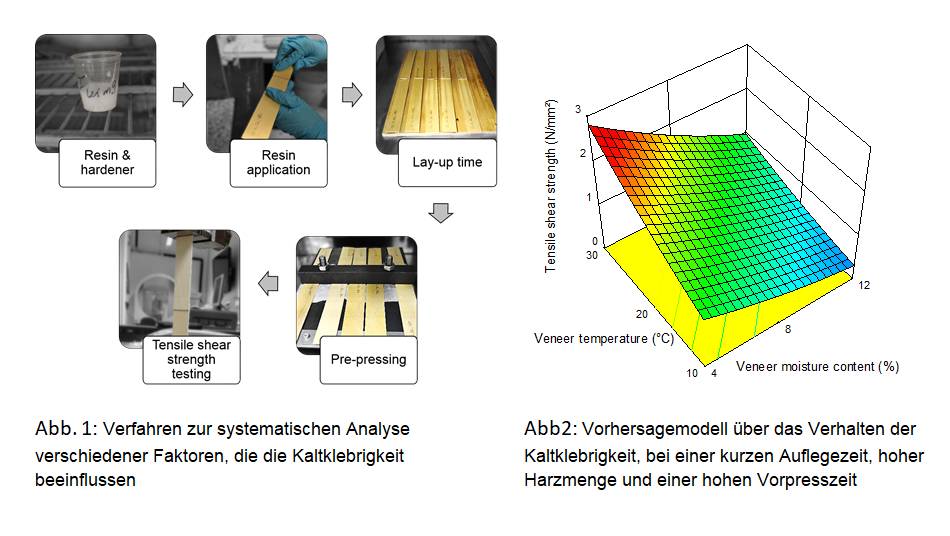

Cold tack of the adhesive is absolutely necessary in plywood production. Insufficient cold tack is usually seen as a typical adhesive problem and leads to complaints. An analytical method has been developed that proves, that many other factors also play a role. For example, cold tack decreases when the wood moisture content increases or increases with temperature. Based on the analytical data, a statistical model was build that predicts how cold tack reacts on the combination of many influencing factors. This model is used to educated plywood pro-ducers, leading to a reduction of failure in plywood production.

On April 27th, 2018 the workshop on Plasma Technologies - Current developments and opportunities for the future will take place in the Kompetenzzentrum Holz GmbH in St. Veit / Glan (W3C). The event will be organized as part of the INTERREG V-A Italy - Austria 2014-2020 funded project ICAP (ITAT1010) - "Innovation through combined applications of plasma technologies".

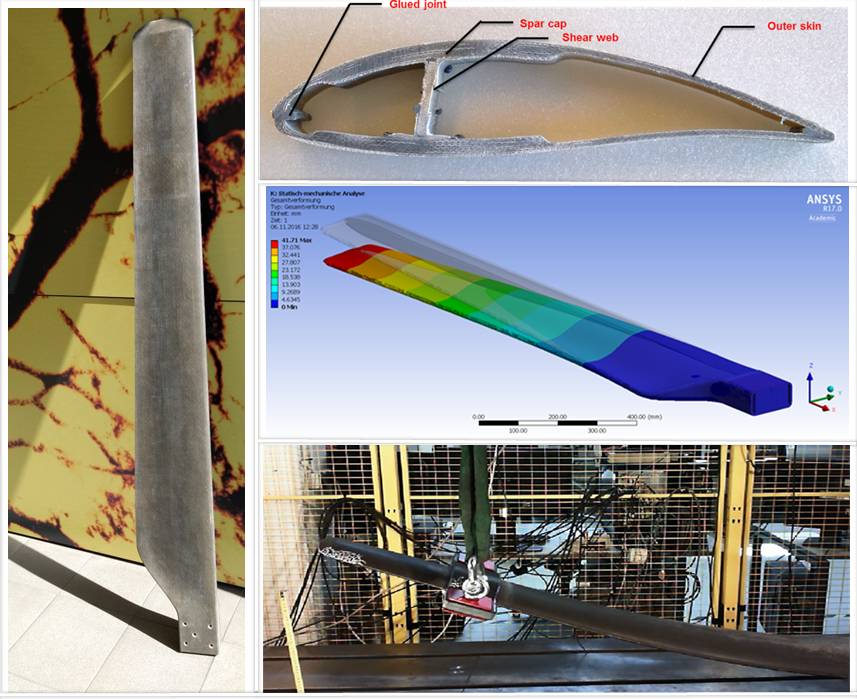

Hemp plants were utilized for constructing rotor blades for small wind turbines in order to build “green energy”-facilities consequently from a sustainable material.

Hochkarätige Gäste aus Forschung und Industrie gaben am Standort Tulln den offiziellen Startschuss für die von der EU mitgeförderten Innovationsprojekte SUSBIND und SUSFERT.

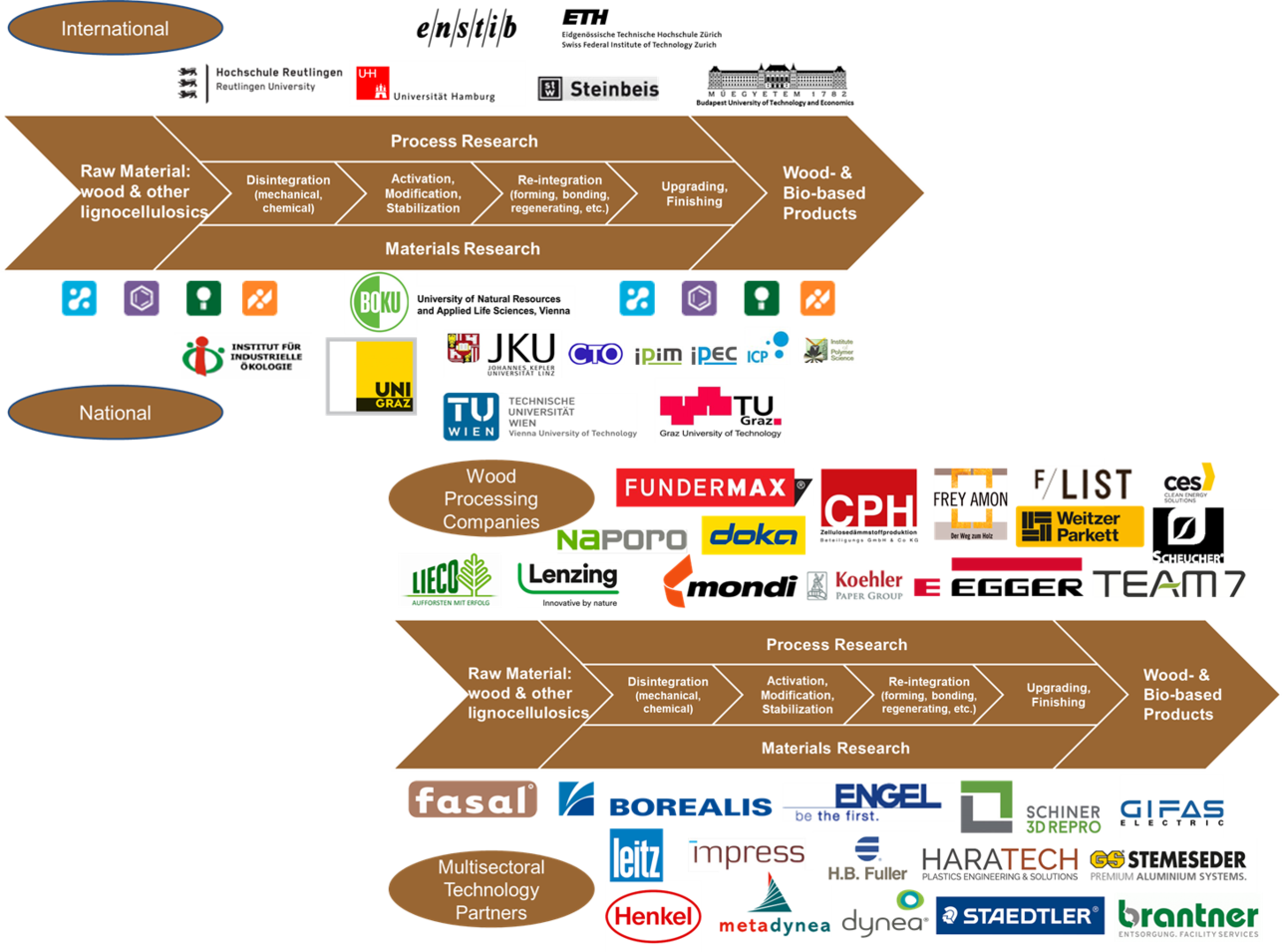

Im Rahmen des COMET-Programms (Competence Centers for Excellent Technologies) konnte sich das Kompetenzzentrum Holz (Wood K plus) nach Abschluss der Evaluierung durch ein internationales Fachkomitee die Finanzierung für weitere vier Jahre sichern. Damit steht dem Zentrum und seinen Partnern für die Programmperiode 2019-2022 ein Forschungsbudget von 22,7 Mio. Euro zur Verfügung.

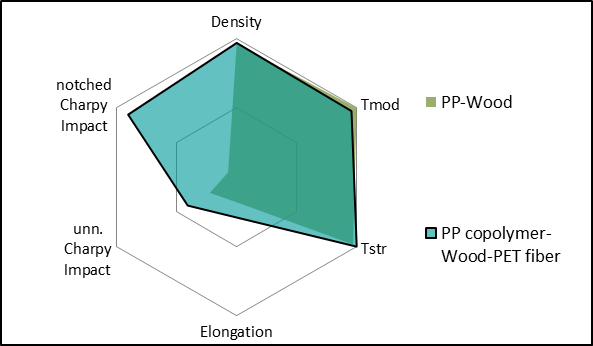

Together with Borealis Polyolefine and Budapest University of Technology, notched impact strength of polypropylene (PP) based Natural Fiber Composites (NFC) has been highly in-creased by the development of innovative hybrid materials. We used special polymeric fibers as impact modifiers for NFC. In the present development, PP impregnated long fibers were applied for the first time as impact modifier for NFC. Longer fibers are more effective rein-forcements in thermoplastics than shorter fibers. Materials with high impact strength, which show improved crash performance, are of importance in the automotive industry.

Closing the loops for process waters in the pulp and paper industry is an important step to minimize the environmental footprint. It enables significant reduction of water consumption, but on the other hand undesired wood components are enriched within the process. In collaboration with Lenzing AG, a highly versatile extraction method was developed to enable characterisation of the diverse components in aqueous samples. The novel method combines the purification, enrichment or fractionation steps and makes therefore process control easier and faster.